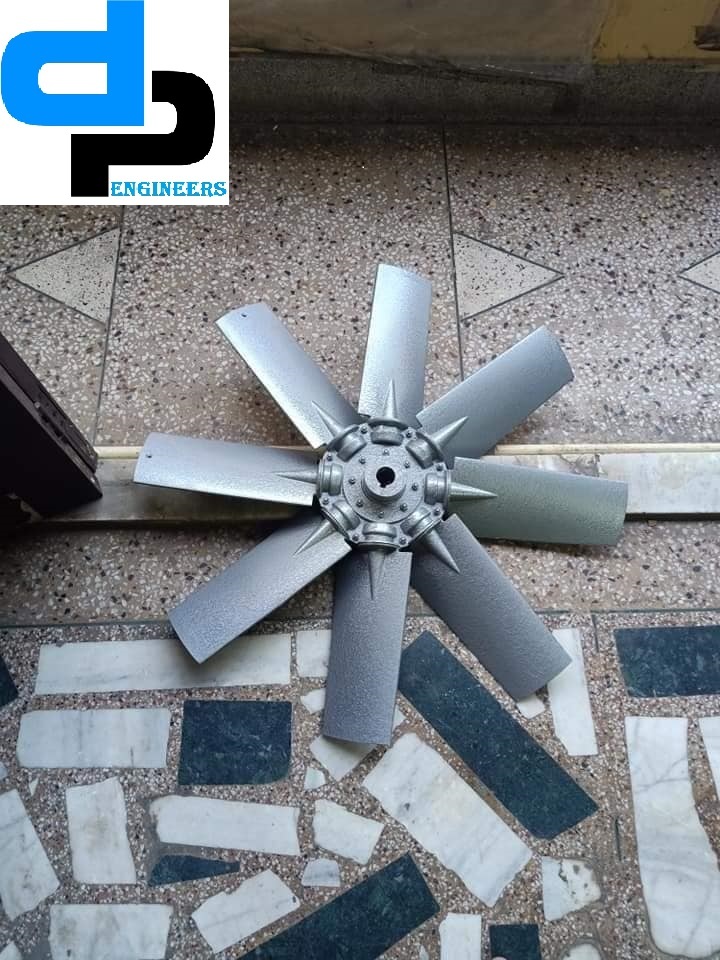

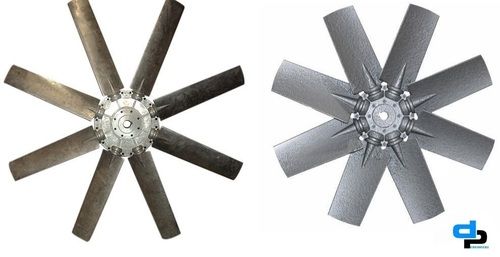

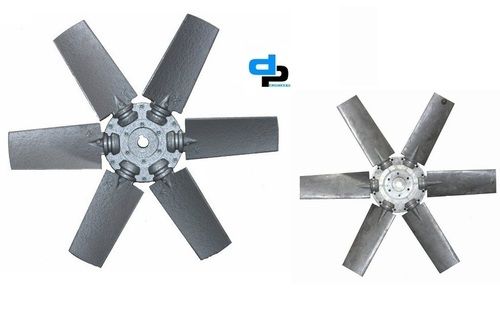

Air Foil Blade Axial Fan

Product Details:

- Pressurization high Pressure

- Product Type Centrifugal Blower

- Material aluminium

- Application Industrial Househol Air knives Packing Soil remediation Food-processing Dental prinitng textile gas analysis Filling Thermoforming

- Noise Level 74 db

- Power Source Electric Blower

- Color white

- Click to View more

Air Foil Blade Axial Fan Price And Quantity

- 8500 INR/Piece

- 10 Piece

Air Foil Blade Axial Fan Product Specifications

- Electric Blower

- Centrifugal Blower

- high Pressure

- 74 db

- white

- aluminium

- Industrial Househol Air knives Packing Soil remediation Food-processing Dental prinitng textile gas analysis Filling Thermoforming

Air Foil Blade Axial Fan Trade Information

- Delhi

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash in Advance (CID) Cash Advance (CA)

- 10-12 Piece Per Day

- 10-12 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Websites : www.dpengineers.in www.dpengineer.in www.dpengineers.co.in www.dpengineer.co.in www.dpengineersindia.com www.dpengineerindia.com www.dpengineersindia.in www.dpengineers.info www.dpengineer.info www.dp-engineers.com www.dpengineerindia.in www.dpengineersindia.net www.dpengineersdelhi.co.in www.dpengineersdelhi.com www.dpengineersdelhi.net

- Middle East Asia

- Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep South India East India Assam Arunachal Pradesh Bihar Chandigarh Delhi Gujarat Goa Jammu and Kashmir Jharkhand Karnataka Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Nagaland Kerala Haryana North India Andhra Pradesh Central India Odisha West India Uttar Pradesh Chhattisgarh All India

Product Description

Air Foil Blade Axial Fan

As A Logical Extension To Our Technological Advances And Innovations, D.P.ENGINEERS Offers Structurally Strong, Hollow, Seamless, Lightweight Construction Blades With Sophisticated Aerodynamic Profiles.

Energy Savings:

Existing Metal Fan Blades Are Designed With A Very Low Cl / Cd Ratio Due To Poor Aerodynamics. Since D.P.ENGINEERS Frp Axial Flow Fans Are Designed With Very Efficient Aerodynamic Blade Profile And High Twist & Camber Characteristics, They Provide A 15-35% Power Savings As Compared To The Metallic & Grp Fans Available In The Market.

Higher Air Flow:

D.P.Engineers Airfoil Fan Blades Provide Up To 12% More Air As Compared To Existing Metallic & Grp Blades Enabling Higher Productivity / Cooling Capacity.

Light Weight:

D.P.ENGINEERS Energy Efficient Fans Blades Are Lightweight Which Minimizes Handling During Maintenance And Results In Less Downtime. The Lighter Weight Of D.P.Engineers Fan Blades Increases The Life Of Some Of The Allied Components Such As The Gearbox, Bearings, And Motor.

Low Noise:

D.P.Engineers Unique Aerofoil Fan Blades Design Helps Reduce The Fan Operational Noise Level Significantly When Compared To The Existing Fans Noise Levels.

Low Maintenance & Vibration Free:

D.P.Engineersmfan Blades Are Moment Balanced For Ease Of Installation And Elimination Of System Vibration. This Will Also Reduce Fan Maintenance And The Frequency Of Replacement.

Corrosion & Erosion Resistant:

D.P.ENGINEERS Fans Are Made From Epoxy And Polyester Resin Systems. This Material Is Immune To Corrosion. Furthermore, The Fan Blade Leading Edges Are Manufactured With Built-In Erosion Protection From Impinging Water Droplets.

Tough & Durable:

D.P.ENGINEERSFan Blades He A Have High Strength To Weight Ratio Compared To Conventional Metallic Blades Enabling A Longer Blade Life. An Optimum Angle Of Incidence Also Avoids Unnecessary Stress On Fan Blades And Prevents Blade Failure.

Advanced Blade Manufacturing:

To Ensure A Higher Quality Product For Our Customers, We Have Adopted A State-Of-The-Art Manufacturing Process Using Advanced Manufacturing Facilities And Stringent Quality Standards. D.P.Engineers Frp Fan Blades Are Made Very Precisely Using Moulds. This Level Of Precision Is Not Possible With The Manufacturing Process Used For The Existing Aluminum / Metal Blades. Both, Casting And Extrusion Manufacturing Processes Have The Expensive Tooling And Face A Challenge In Generating Blade Profiles With High Twist And Camber Characteristics. This Has Restricted Them To Retain Low Camber In Their Design. Further, There Is A High Level Of Inconsistency In Manufacturing Tolerances Of Blades Or Dimensional Stability Of The Metallic Blades Causing Further Deterioration Of Fan Performance. There Is Also A High Level Of Inconsistency In The Manufacturing Tolerances And The Dimensional Stability Of Metallic Blades Causing A Further Reduction In Fan Performance. In Order To Prevent These Inconsistencies, D.P.ENGINEERS Fans Are Manufactured Using Advanced Vacuum Infusion Technology Enabling Uniform Weight And Wall Thickness.

- Better Fibre To Resin Ratio

- Lower And More Consistent Blade Weight

- Uniform Wall Thickness

- Higher Aerodynamic Accuracy,Consistency And Superior Surface Finish

- Increased Blade Strength

- Maximized Fibre And Resin Properties

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+