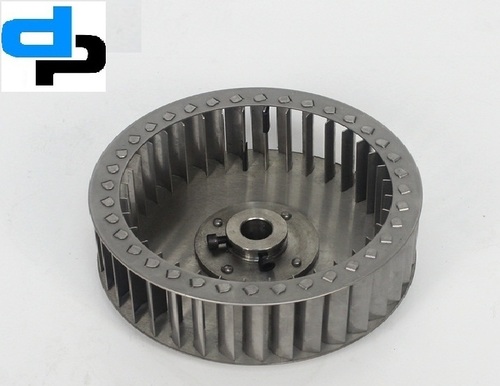

DIDW Centrifugal Fan 610 MM X 455 MM

DIDW Centrifugal Fan 610 MM X 455 MM Specification

- Life Span

- 10-12 Years (approx.)

- Pressure Range

- 200-700 Pa

- Output Power

- 2.2 kW

- Flow Rate

- Up to 9350 m/h

- Motor Power

- 2.2 kW

- Max Pressure

- 700 Pa

- Power

- 3 HP

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel / Galvanized Steel

- Capacity

- Up to 5500 CFM

- Pressure

- Up to 700 Pa

- Application

- Industrial ventilation, HVAC, Air handling units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- Below 82 dB(A)

- Power Source

- Electric

- Voltage

- 415 V AC

- Weight

- Approx. 108 kg

- Dimension (L*W*H)

- 610 mm x 455 mm x 500 mm (approx)

- Color

- Blue / Grey

DIDW Centrifugal Fan 610 MM X 455 MM Trade Information

- Minimum Order Quantity

- 2 Pieces

- Main Domestic Market

- Dadra and Nagar Haveli, Meghalaya, South India, Central India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Delhi, Gujarat, West India, Chhattisgarh, Himachal Pradesh, All India

About DIDW Centrifugal Fan 610 MM X 455 MM

DIDW Centrifugal Fan 610 MM X 455 MM

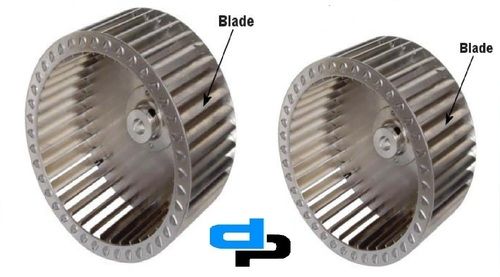

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 65 | DP 24 21 | 610 X 530 X 500 | 24 X 21 | 35 MM,40 MM,& 1.5'' | AL. / GI. |

Versatile Performance and Customization

Designed to meet a variety of industrial air movement needs, this centrifugal fan offers flexibility in impeller type, air discharge direction, and material choice (mild or galvanized steel). Its robust construction ensures consistent operation in demanding environments, making it suitable for factory floors, HVAC, and specialized ventilation.

Durability and Easy Maintenance

With sealed-for-life ball bearings and a powder-coated or enamel-painted finish, the DIDW Centrifugal Fan is built for longevity and minimal maintenance. The IP55 enclosure and F class insulation guarantee reliable performance even in challenging conditions, operating at temperatures from -10C to +60C.

Efficient & Quiet Operation

Benefiting from advanced aerodynamics, this fan achieves up to 80% efficiency and keeps noise levels below 82 dB(A). Its 2.2 kW motor and belt drive design deliver optimal airflow and pressure while consuming moderate power, making it a cost-effective solution for continuous ventilation.

FAQs of DIDW Centrifugal Fan 610 MM X 455 MM:

Q: How is the DIDW Centrifugal Fan installed and mounted?

A: This centrifugal fan is base mounted for stable installation on flat surfaces. It is typically anchored to prevent vibration and ensure safety in industrial or commercial settings.Q: What are the main applications of this centrifugal fan?

A: The fan is widely used for industrial ventilation, HVAC systems, and air handling units. It is suitable for use in factories, large commercial buildings, and environments where efficient air movement is required.Q: When should I choose between a backward or forward-curved impeller type?

A: Your selection depends on the required operating pressure and airflow. Backward-curved impellers are ideal for higher pressures and efficiency, while forward-curved impellers are more suitable for higher airflow at lower pressures.Q: Where can the air discharge direction be customized?

A: Yes, the air discharge direction can be tailored during the manufacturing process to suit your specific installation requirements, ensuring efficient integration with your existing ductwork or airflow system.Q: What maintenance is needed for the DIDW Centrifugal Fan?

A: Minimal maintenance is required due to sealed, greased-for-life ball bearings and a corrosion-resistant finish. Routine inspections are recommended to ensure optimal operation.Q: How does this fan benefit my operation compared to others?

A: This fans high efficiency (up to 80%), robust design, and low noise level make it cost-effective and reliable. Its long service life (1012 years) ensures sustained performance with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Dimension (L*W*H) : 250 mm x 280 mm

Motor Speed : 2800 RPM

Capacity : 1200 CFM

DIDW Centrifugal Fan 151 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Dimension (L*W*H) : 151 mm x 100 mm x 152 mm

Motor Speed : 2850 RPM

Capacity : 800 m3/h

DIDW Centrifugal Fan 160 MM X 200 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Dimension (L*W*H) : 160 mm x 200 mm

Motor Speed : 2800 RPM

Capacity : 1500 CFM

DIDW Centrifugal Fan 380 MM X 380 MM

Price 10000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Dimension (L*W*H) : 380 mm x 380 mm

Motor Speed : 1440 RPM

Capacity : 1500 CMH

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS