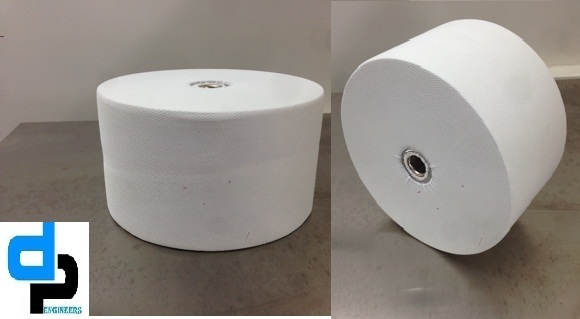

Triple R Filter Elements

Triple R Filter Elements Specification

- Connecting Type

- O-ring Seal / End Cap

- Efficiency (%)

- Up to 99.9%

- Temperature Range

- -25C to +120C

- Pressure

- Maximum 10 bar

- Media Type

- Cellulose, Microglass, Stainless Steel Mesh

- Flow Rate

- From 1 LPM up to 600 LPM

- Capacity

- Depends on size and application

- Cleaning Method

- Replaceable / No cleaning required

- Filtration Grade

- Fine (double checked: matches above specification)

- Filter Type

- Cartridge / Replacement Element

- Condition

- New

- Material

- Cellulose, Synthetic Fiber, Stainless Steel

- Mesh

- As per requirement / Customizable

- Diameter

- Varies by model (Standard: 60mm to 180mm)

- Construction

- Multi-layered, Pleated or Depth

- Medium Filter

- Oils, Hydraulic Fluids, Lubricants

- Weight

- From 200 g up to 2 kg depending on size

- Shape

- Cylindrical

- Feature

- High dirt-holding capacity, Long service life, Precise filtration, Easy replacement

Triple R Filter Elements Trade Information

- Minimum Order Quantity

- 10 Paints

- FOB Port

- Delhi

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 7 Days

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Tripura, Meghalaya, Uttarakhand, Daman and Diu, South India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Manipur, Jammu and Kashmir, Jharkhand, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Dadra and Nagar Haveli, Uttar Pradesh, Karnataka, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About Triple R Filter Elements

Triple R Filter Elements

Triple R Filter Elements With year of experience and professional working, we are offering wide range of Oil Filter Elements to our clients. This product is widely used in oiling and manufacturing industries and its quality design provide steady base in filtration process. Our products are quality tested and are compounded with fine quality of material.

Features:

- Long life element

- Special cellulose element medium that allows higher dirt absorbing

- Perfect for high viscosity oil (VG220-320-460)

- Media material: cellulose

Specifications:

- Clapboard: without Clapboard

- Filter Number: 1

- Medium Material: Fiberglass

- Efficiency: High Precision

- Filtration Grade: HEPA Filter

- Type: Cartridge Filter

- Type : PAPER

- Brand Name : D.P.ENGINEERS

- Condition : NEW

- Warranty : NO

- Model Number : D.P.ENGINEERS

- Place of Origin : DELHI

Engineered for Versatile Performance

The Triple R Filter Elements are suitable for a diverse range of hydraulic and lubrication systems, with adaptable designs for various industrial oil filtration applications. Their multi-layered constructionavailable in pleated or depth formatsdelivers finely controlled contamination management in demanding environments.

Premium Materials and Customization

Choose from filter elements featuring end caps in plastic, steel, or aluminum, and inner cores made of galvanized or stainless steel. With filter media ranging from cellulose and microglass to stainless steel mesh, you can request mesh and size variations to precisely match your application requirements and achieve exacting filtration standards.

Reliable Sealing and High Efficiency

Each filter uses a special triple sealing technique and O-ring connections to provide a secure fit and prevent leakage. With a maximum particle retention of up to 1 micron and efficiency up to 99.9%, they maintain system cleanliness and asset protection even under temperatures between -25C and +120C.

FAQs of Triple R Filter Elements:

Q: How do I select the appropriate Triple R Filter Element for my hydraulic or lubrication system?

A: Selection depends on your systems flow rate, operating pressure (up to 10 bar), temperature range, desired particle retention (as fine as 1 micron), and required diameter (typically 60mm180mm). Consider the filter media, end cap material, and whether a bypass valve is needed. OEM replacement options are also available for compatibility.Q: What are the benefits of using Triple R Filter Elements with triple sealing technology?

A: The special triple sealing technique ensures optimal sealing performance, preventing bypass and leakages. This guarantees reliable filtration quality, helping to maintain the cleanliness of hydraulic fluids and lubricants while extending the service life of both the filter and associated equipment.Q: When should I replace a Triple R Filter Element, and is cleaning required?

A: Triple R Filter Elements are designed for easy replacement and do not require cleaning. Replacement intervals depend on operating conditions, flow rate, dirt load, and system maintenance practices. It is advisable to monitor pressure drop or follow manufacturer-recommended maintenance schedules for timely replacement.Q: What packaging options are available for Triple R Filter Elements?

A: All filter elements are individually packed, either in polybags or boxes, to ensure the filter remains contamination-free during storage and transportation.Q: Where can Triple R Filter Elements be used, and are there OEM replacement options?

A: They are widely used in hydraulic and lubrication systems, industrial oil filtration, and similar applications in various industries. OEM replacement elements compatible with major brands are available, ensuring seamless integration into existing filtration setups.Q: How does the multi-layered construction enhance filtration performance?

A: The multi-layered, pleated or depth design increases surface area and dirt-holding capacity, ensuring efficient particle capture and supporting long filter service life even under heavy contaminant loads.Q: What is the process for replacing a Triple R Filter Element?

A: To replace, stop the system, depressurize, remove the old cartridge, clean the housing if necessary, and install a new filter. Ensure correct seating using the O-ring or end cap for proper sealing, then resume operation as per the system manual.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

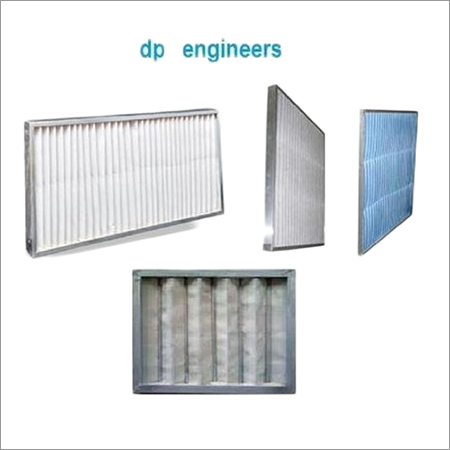

More Products in HVAC Filters Category

Oil Filter Element

Minimum Order Quantity : 10 Pieces

Filter Type : Oil Filter Element

Diameter : Up to 120 mm

Shape : Cylindrical

Weight : 200700 gm

RRR Filter Cartridge

Price 2500 INR

Minimum Order Quantity : 10 Pieces

Filter Type : Cartridge Filter

Diameter : Standard: 67 mm (custom sizes available)

Shape : Cylindrical

Weight : Approx. 500 grams (depends on size/model)

HEPA Terminal Filter Boxes

Price 18000 INR / Piece

Minimum Order Quantity : 10 Pieces

Filter Type : Terminal HEPA filter

Diameter : Standard size: 610 mm x 610 mm (also available in customized sizes)

Shape : Rectangular/box

Weight : Typically 814 kg (varies by dimension/model)

Air Washer Filters

Price 800 INR / Piece

Minimum Order Quantity : 100 Pieces

Filter Type : Air Filter

Diameter : Customizable

Shape : Rectangular / Custom Shape Available

Weight : Lightweight / Varies as per size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS